Brewery Profitability Lesson

Keys for tracking and analyzing cost of goods sold (COGS)

Running a profitable brewery is a balancing act that goes far beyond the fermentation sciences. Brewers must have everything required to brew and package beer in the near-term but be careful not to amass a surplus of raw ingredients, aluminum, glass, and cardboard that would create space issues and negatively impact cash flow.

We know most brewers are tracking their cost of goods sold in some way, whether it be with spreadsheets or a software program. But the level of detail in the data and how it is then used, can make the real difference. You cannot hope to improve efficiency or increase profitability without metrics to measure this. And if you’re not analyzing these metrics, comparing output with sales revenue, and tracking the true cost of making your beer – what is this data worth?

If you’re not tracking profitability, you won’t know how to be more efficient, or increase your net profit. And, if you don’t know how profitable you are – you can’t plan for the future at all. Here are the four areas of brewery operations you should be paying close attention to, when analyzing this data and measuring profitability.

1. Material costs

As a brewer, you want to ensure you are only holding on to raw materials as you use them – you don’t want to be sitting on stock. This could create space issues and impact your cash flow. On top of that, brewers and operations staff need to factor in the costs of all goods and materials that come into the brewery.

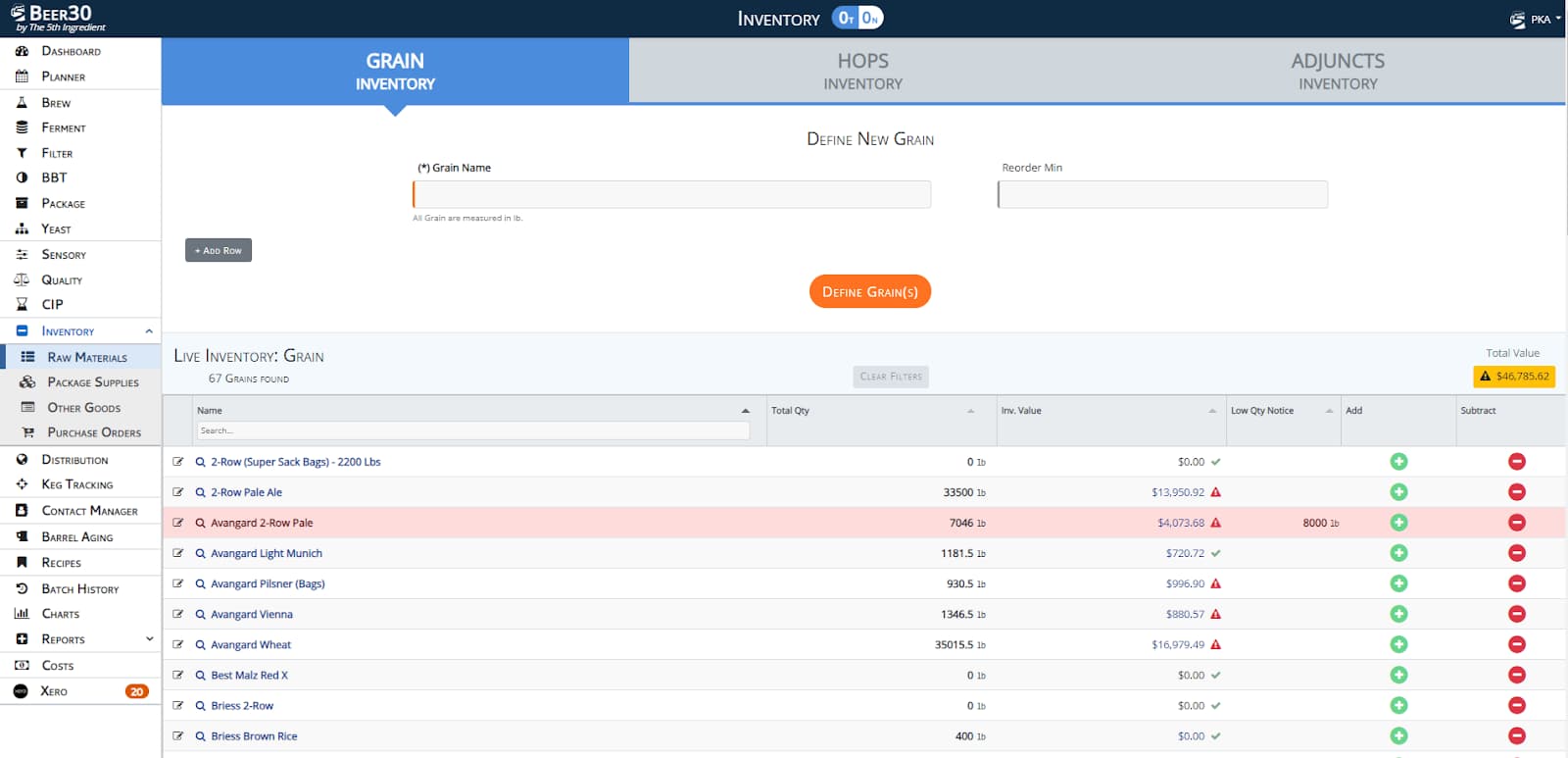

On a monthly basis, you should be able to pull up a report to see the total $ value for each set of raw materials and packaging supplies that are sitting on your shelf and in inventory to properly assess what your assets are for your material costs.

What brewery professionals need are reliable, easy-to-use tools that provide easy access to accurate cost data and the ability to manipulate it as needed. Beer30 is a single tool that lines up costing information side-by-side, then goes a step further, comparing material costs against profit at the click of a button.

Our side-by-side cost summary feature conveys what is coming in against what is going out, detailing:

- Monthly losses

- Losses per brew / packaging run (empty bottles cans being wasted or destroyed, accidents, etc.)

- Downtime inefficiencies

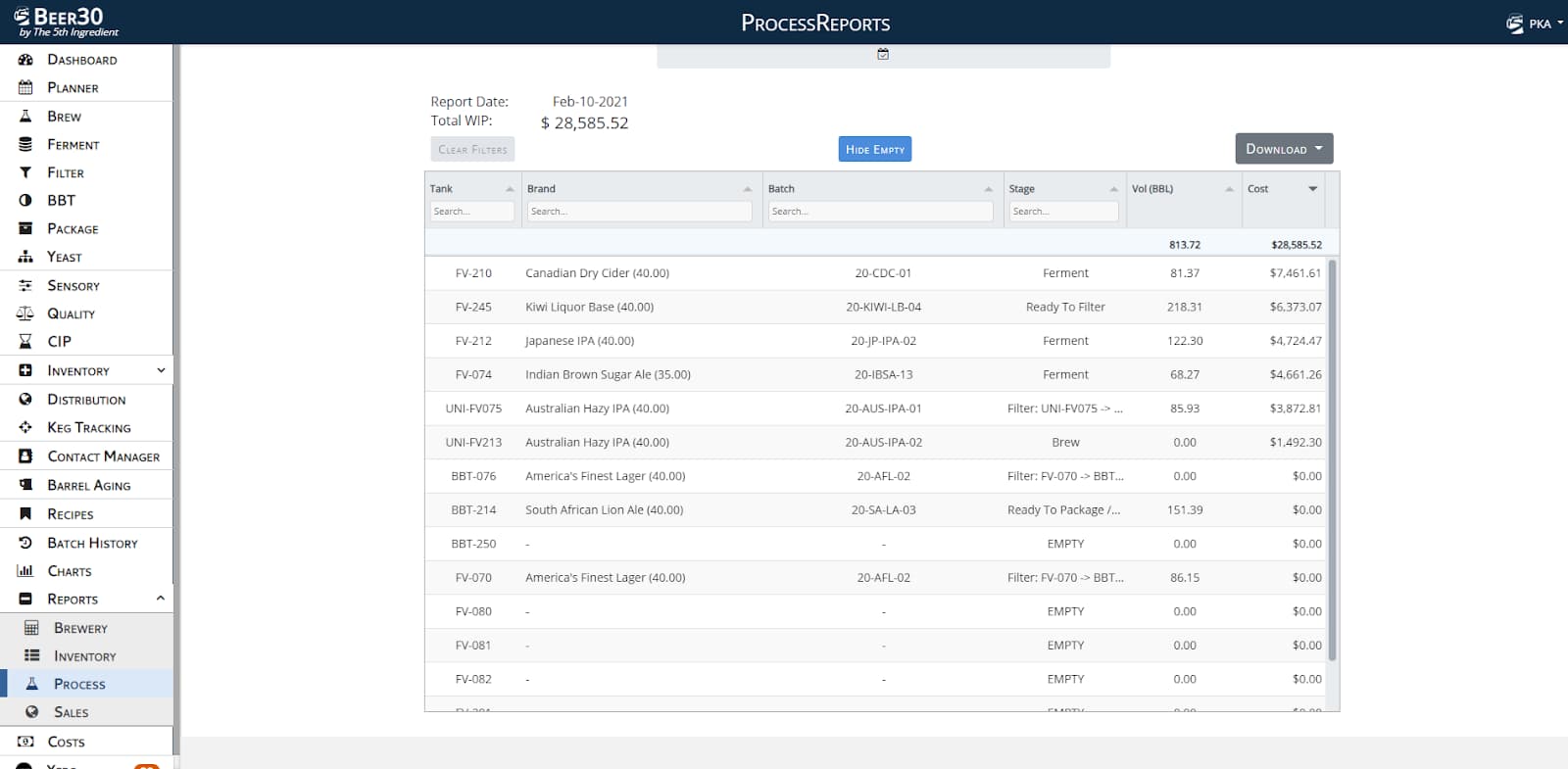

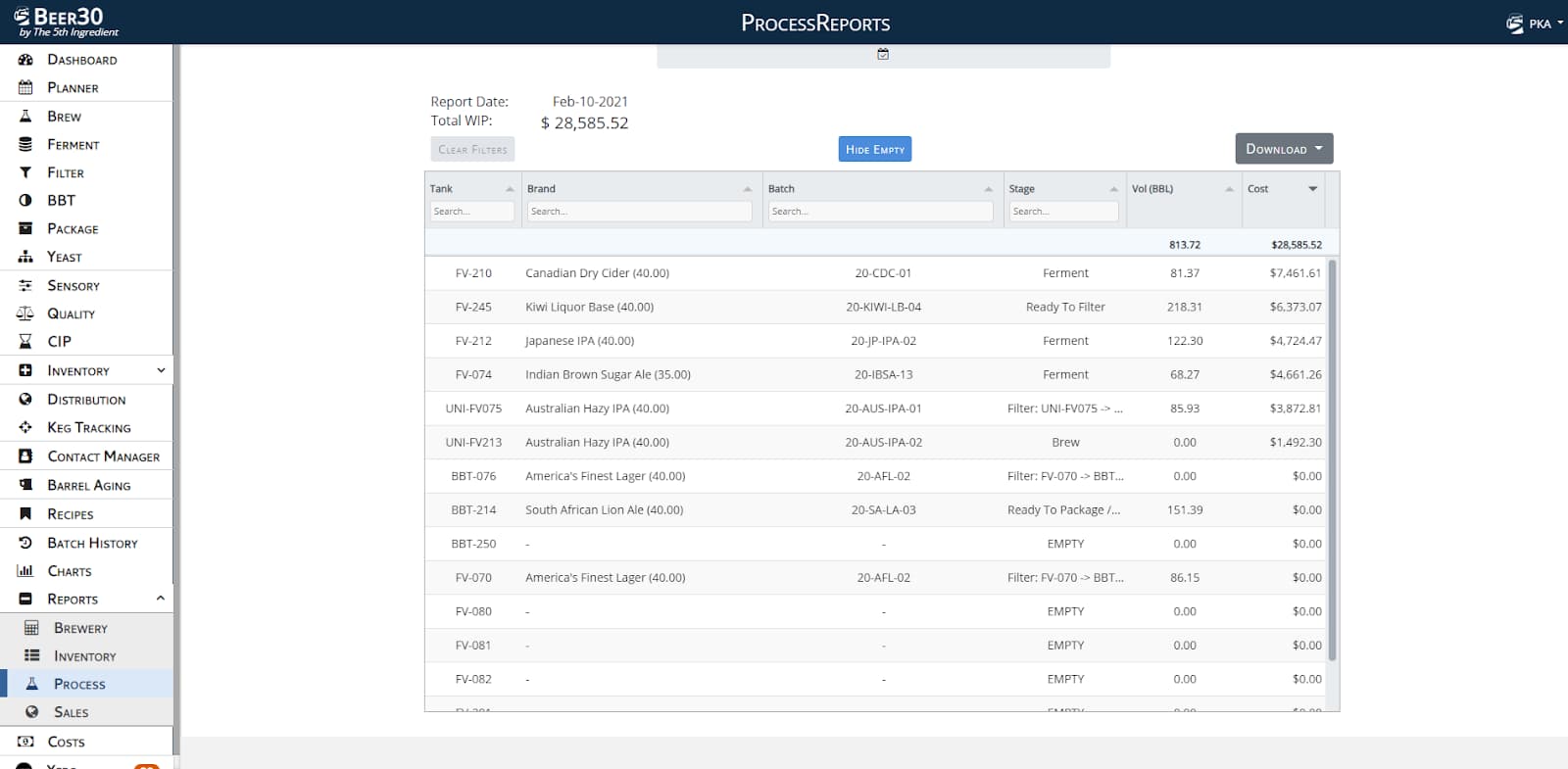

2. Brew Day, Work In Process (WIP), Packaging Day

Once raw materials are taken from storage and put into production – costs are moved from the raw material inventory to Work in Process (WIP). The balance in WIP represents the value of the raw materials that make up the beer in the tank. There are several factors that need to be considered when calculating the WIP costs and how they relate to your overall cost of goods sold.

Key software features here are being able to properly transfer all costs associated with tank splits and merging. This is super important when you’re looking at taking a base beer, and splitting it up to make variations — i.e. brewing into a 15 BBL tank a base IPA, and then splitting up into two tanks to get a 7 BBL Pineapple IPA and keep an 8 BBL Habanero IPA.

We also advise our customers to include in their WIP and brewing data other costs, such as:

- Hourly labor

- Other external factors, such as rent

- Yeast costs associated with fresh pitches / repitches / harvested

As package day rolls around, it is also super critical to include all package supplies too. This includes items like:

- Contract packaging costs associated with third party companies

- Bottling :: Empty bottles, labels, crowns, carriers, cartons

- Canning :: Empty or pre-printed cans, labels, lids, PakTechs

- Kegs :: Keg shell costs, keg collars, and keg caps

Each factor goes into making an actual overall COGS, for the beer.

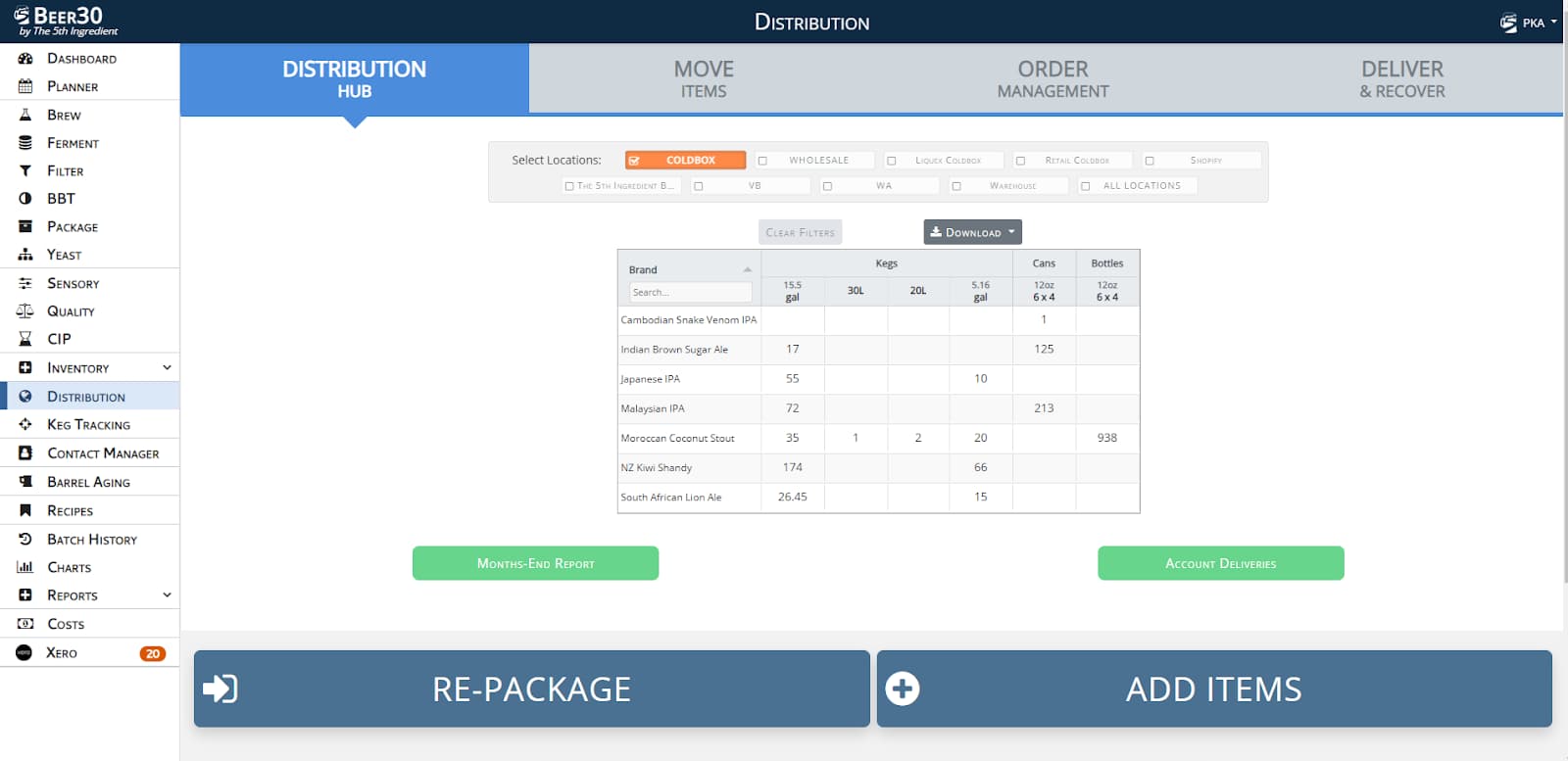

3. Finished Goods Inventory

Finished goods inventory refers to the quantity of manufactured products in stock that are available for customers to purchase. It’s important to then add in the overall value of these products. When you use the right software system to track the components that go into making each packaged goods item, the individual COGS can be immediately calculated.

With the finished goods calculation, you should look at it on a batch by batch comparison for reporting purposes. You should see immediately if a batch is higher or lower than the Target COGS, which is the ‘gold standard’ for that beer.

It should be constantly monitored, to ensure your business is on the right track. This is why using software to track your data makes your life easier. It is all being tracked behind the scenes, ready and waiting for you to access, whenever you need it.

4. Sales vs. COGS

And of course, the final piece of the puzzle is comparing your gross revenue against your cost of goods sold. It’s the all-important formula for a successful business – sales revenue, minus cost of goods sold is your gross profit. And without profitability, a business will not survive.

Having this data on your brewery operations available anytime is not just convenient – it is crucial. You should be able to identify trends happening with sales on your brews, see where the demand is, and compare your revenue directly against your COGS. Constantly monitoring this data also helps you easily detect theft or missing inventory from the coolroom / coldbox.

By using a brewery management software like Beer30, you can take all the factors associated with COGS – raw materials, ingredients, labor, overhead, packaging supplies, cost of yeast, and more at each stage in the brewing process – and make them all part of the bigger picture.

In a single click in our Batch History tool, you can cycle through each brand and batch and see the EXACT dollar value per BBL / HL / L – and NEVER have to look at assumed average costs. Then you can tie all this information together to truly understand how things are progressing, and what your future looks like. Financial and operating budgets, for both your current and following financial year are determined by the profitability of your brewery.

Article Retrieved via the 5th Ingredient, creators of Beer30 brewery management software platform and Craft Brewing Business written by CBB Editorial Staff.

Photo Credit: the 5th Ingredient and Craft Brewing Business.

Beer CPA – “We Give Craft Breweries More Freedom and Peace of Mind”

A Craft Brewery CPA Firm that’s Tech Savvy, Responsive, and Business Smart.